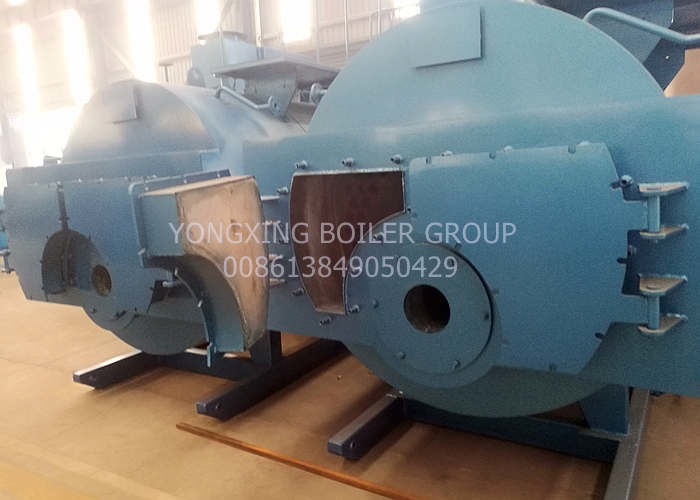

Safety value 2t gas fired boiler efficiency and industrial gas boiler for palm oil processing plant with quality assured

The industrial gas boiler produced by the company adopts a three-return wet-back shell structure, and the fuel is subjected to micro-positive pressure combustion in the corrugated furnace. The high-temperature flue gas flows through three return strokes, which can effectively reduce the exhaust gas temperature and improve the thermal efficiency of the equipment. The water inlet of the boiler is equipped with a water vapor mixing device to increase the temperature of the feed water, avoid boiling phenomenon caused by excessive local water temperature, and increase the separation device to further improve the quality of the steam.

Structural features

1. High furnace strength

The use of the corrugated furnace not only increases the radiation heat transfer area, but also effectively reduces the expansion stress of the furnace and improves the combustion efficiency of the fuel.

2. Advanced welding process

The boiler adopts the process of first expanding and then welding, eliminating the gap between the pipes and avoiding the corrosion phenomenon that may occur in the high temperature zone.

3, the smoke box insulation effect is good.

The smoke box adopts double-layer insulation structure, which can recover the waste heat from the boiler flue gas to the utmost extent.

4. High gas fired boiler efficiency

A condenser is added to the tail to increase the inlet water temperature of the boiler, reduce the exhaust gas temperature, and greatly improve the combustion gas fired boiler efficiency of the industrial gas boiler.

5.Digital manufacturing, beautiful appearance

The front and rear smoke box panels of WNS series fuel/gas boilers are cut by CNC plasma cutting machine, which is neat and beautiful.

6. The equipment is fully automatic, easy to operate and maintain

WNS series fuel/gas boilers have full-automatic operation characteristics, and the combustion, water level, temperature and steam pressure are automatically adjusted and automatically protected.

Classification and Application

1. According to different fuels, industrial gas boiler can be divided into natural gas boilers, city gas boilers, coke oven gas boilers, liquefied petroleum gas boilers, and biogas boilers.

2. Heating, chemical, food, tobacco, textile, printing and dyeing, feed, medicine, building materials, brewing, rubber, hospital and so on.

High efficiency gas steam boiler data Sheet

|

Model

|

Rated evaporation capacity(t/h)

|

Working Pressure(Mpa)

|

Steam Temperature(℃)

|

Feed Temperature(℃)

|

Transportation Size(m)(L×W×H)

|

|

WNS1-0.7-Y(Q)

|

1

|

0.7

|

170

|

20

|

3.3×1.8×2.1

|

|

WNS1-1.0-Y(Q)

|

1

|

1

|

184

|

20

|

3.3×1.8×2.1

|

|

WNS2-1.0-Y(Q)

|

2

|

1

|

184

|

20

|

4.4×2.1×2.5

|

|

WNS2-1.25-Y(Q)

|

2

|

1.25

|

194

|

20

|

4.4×2.1×2.5

|

|

WNS4-1.25-Y(Q)

|

4

|

1.25

|

194

|

20

|

4.7×2.5×2.9

|

|

WNS4-1.6-Y(Q)

|

4

|

1.6

|

204

|

20

|

4.7×2.5×2.9

|

|

WNS6-1.25-Y(Q)

|

6

|

1.25

|

194

|

20

|

5.9×2.6×3.0

|

|

WNS6-1.6-Y(Q)

|

6

|

1.6

|

204

|

20

|

5.9×2.6×3.0

|

|

WNS8-1.25-Y(Q)

|

8

|

1.25

|

194

|

105

|

5.9×2.8×3.1

|

|

WNS8-1.6-Y(Q)

|

8

|

1.6

|

204

|

105

|

5.9×2.8×3.1

|

|

WNS10-1.25-Y(Q)

|

10

|

1.25

|

194

|

105

|

7.7×2.8×3.1

|

|

WNS10-1.6-Y(Q)

|

10

|

1.6

|

204

|

105

|

7.7×2.8×3.1

|

|

WNS15-1.25-Y(Q)

|

15

|

1.25

|

194

|

105

|

7.0×3.1×3.6

|

|

WNS15-1.6-Y(Q)

|

15

|

1.6

|

204

|

105

|

7.0×3.1×3.6

|

|

WNS20-1.25-Y(Q)

|

20

|

1.25

|

194

|

105

|

8.3×3.4×4.0

|

|

WNS20-1.6-Y(Q)

|

20

|

1.6

|

204

|

105

|

8.3×3.4×4.0

|

Product reference of commercial gas boilers

1 Pakistan WNS1-1.0-Y (Q) Application: Chemical plant

2 Indonesia WNS2-1.0-Y (Q) Application: Building industry

3 Thailand WNS1-1.0-Y (Q) Application: Laundry room

4 Malaysia WNS8-1.25-Y (Q) Application: Chemical industry

5 Indonesia WNS6-1.25-Y (Q) Application: Textile industry

Packing list of commercial gas boilers

1 Boiler main part 1set

2 Imported gas/oil burner 1set

3 Electric control box 1set

4 Valve & Gauge used on boiler main part 1set

5 Feeding water Pump 2set

6 Smoke chimney 1set

7 Water treatment equipment 1set

8 Steam distributor 1set

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!