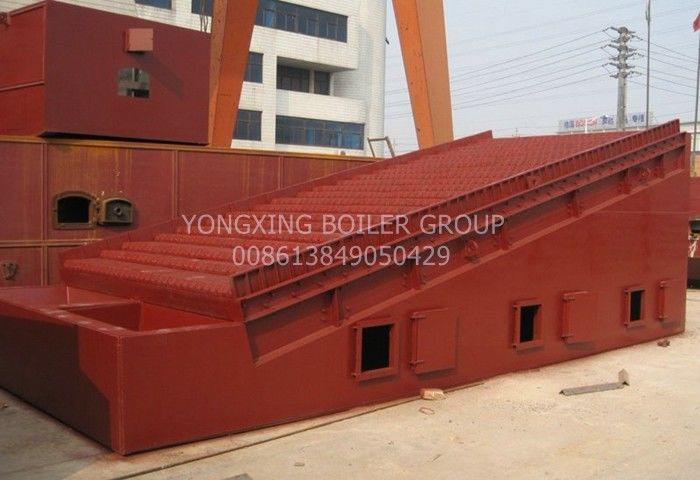

8ton/1.6MPa horizontal double drum reciprocating grate anthracite boiler steam boiler

Features

1. The granular fuel (wood of edge, bark, π, etc.), through the belt feeder hopper, before they are sent into the furnace into the grate let into the chamber by hydraulic device, at this point, the reciprocating grate will push forward and began to make grate surface formation even under fuel the fire of the bed.

Reciprocating grate is composed of an array of fixed grate and active grate, which is pushed by a hydraulic cylinder.

2. Grate has a level as Angle of 20 °, the fuel in the activity under the action of grate after moving gradually to the furnace, and disturbance in the combustion step by step to do.

Required for combustion air from the blower into the grate wind chamber, through the small hole on the link and wind slot into the furnace, in order to protect is combustion of oxygen, each room is equipped with damper wind, according to π adjusted with the quantity of air required for the combustion phase with the wind.

The advantage of a grate furnace is that it does not require pretreatment of waste.

The technology is mature and widely used in foreign countries. Its disadvantages are as follows:

1. Furnace row must be heat-resistant, during long-term continuous operation, the thermal stress must remain unchanged, so that the furnace row material requirements, and the processing of the furnace row is complex, because the furnace row needs to rotate, low reliability and high energy consumption constitute its problems.

2. Because of the complex composition of garbage, it is difficult to keep the common grate moving uniformly in the whole grate and to burn uniformly and completely.

3. It is difficult for the grate to adapt to refuse incineration with a wide range of moisture content, because the waste with high moisture content needs a wide dry area, which makes it difficult for the waste with high water content to be completely burned.

4. More difficult to control furnace temperature, waste slag at above 1000 ℃, and 1050-1100 ℃ in the softening and viscous state, become the special corrosive substance, may be corrosion of furnace wall, at the same time under high temperature condition Nox concentration increased.

5. It is difficult to realize large-scale furnace and remove HCI gas in the furnace. Special equipment and HCI removal equipment need to be installed in the tail, which increases the investment cost.

6. It is necessary to set up special sewage treatment facilities for refractory landfill leachate.

7. The grate furnace is not only complex to manufacture, high cost, but also large in size and covers a large area.

Data sheet of reciprocating grate stoker

Main technical Parameters of

Reciprocating (Stepping) Grate Combustion Device |

Boiler Capacity

(t/h) |

Active grate

area (m2) |

Active Width (mm) |

Reciprocate Length

(mm) |

Angle Grate

(deg) |

| 4t/h |

6 |

997 |

6000 |

Optional |

| 6t/h |

7.5 |

997 |

6500 |

Optional |

| 8t/h |

8.9 |

997 |

6500 |

Optional |

| 10t/h |

10.5 |

1197 |

7500 |

Optional |

| 15t/h |

14.6 |

997 |

7000 |

Optional |

| 20t/h |

20.7 |

997 |

7500 |

Optional |

| 25t/h |

24.6 |

997 |

7500 |

Optional |

| 30t/h |

28.6 |

997 |

8000 |

Optional |

| 40t/h |

34.5 |

997 |

7900 |

Optional |

| 60t/h |

48.7 |

997 |

6500 |

Optional |

| 100t/h |

90.7 |

997 |

8500 |

Optional |

Applications

Furnace coal fired chain grate stoker can be applied in chemical plant, university, food factory, beverage factory, cannery, textile mills, paper mill, sugar plant, central heating and other industries.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!