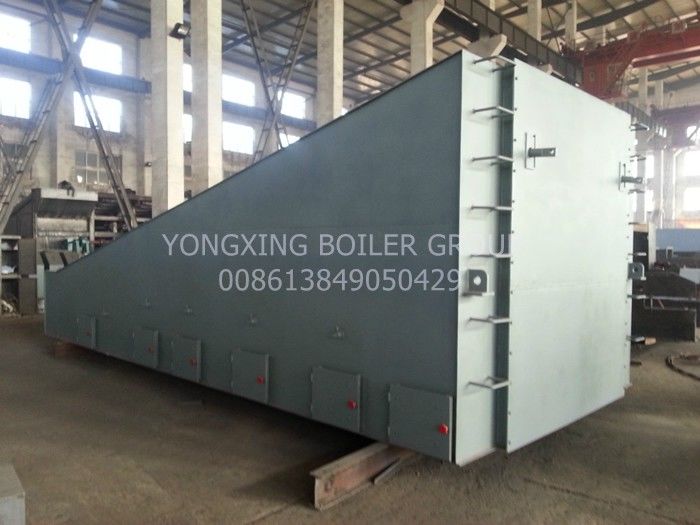

Biomass Furnace Reciprocating Grate For Steam Boilers Heating Of Factory Fire Stoker

Features

1. A step-type horizontal reciprocating grate domestic garbage incinerator mainly solves the problem that the existing chain type mobile grate cannot effectively turn over the garbage, resulting in incomplete combustion of garbage.

2. It includes pusher, hopper, chute, secondary combustion chamber, furnace chamber, reburner, booster, grate assembly, furnace body steel frame, slag outlet, etc. The grate is always a horizontal reciprocating grate with ladder drop, and is divided into preheating and drying zone, combustion zone, and burning zone in the whole length of the grate;

A ladder drop is arranged between the dry area and the combustion area grate;

3. The grate surface is connected by independent multiple grate plates, adjacent grate plates are overlapped up and down, one row of grate plates is fixed, and the other row of grate plates reciprocates.

The furnace is automatically controlled, highly mechanized, highly efficient and easy to operate.

It is mainly suitable for centralized incineration of household garbage.

Advantages:

1. The height of the horizontal reciprocating grate is lower than that of the inclined reciprocating grate, which can effectively save the area of the boiler room, thereby reducing the installation and use cost of the user.

2. In the horizontal reciprocating grate, through the operation of the equipment, the fuel layer (coal layer) can be uniformly covered on the grate, and at the same time, compared with the conventional grate, the internal connection of the grate is relatively tight, and there is no air leakage. The area, so that the wind speed through the coal seam is relatively uniform, the content of coal ash after combustion is significantly reduced.

3. The coal seam is wave-shaped on the horizontal reciprocating grate, and its surface area is 30% to 50% larger than the horizontal surface area of the grate. Therefore, the flow rate of the flue gas leaving the surface of the coal seam is relatively slow, so that the amount of fly ash is reduced compared with the chain grate. 10%.

4. The combustion efficiency of the fuel in the horizontal reciprocating grate is relatively high. Therefore, the furnace temperature is high and the combustion is relatively sufficient, so that coals with strong coking properties can be burned. It can also burn cohesive biomass fuel, which greatly improves the adaptability of the grate to fuel.

5. The fuel preparation and dust removal equipment is simple, the overall cost, low operating cost and simple operation management.

Data sheet of reciprocating grate stoker

Main technical Parameters of

Reciprocating (Stepping) Grate Combustion Device |

|

Boiler Capacity

(t/h) | Active grate

area (m2) | Active Width (mm) | Reciprocate Length

(mm) | Angle Grate

(deg) |

| 4t/h | 6 | 997 | 6000 | Optional |

| 6t/h | 7.5 | 997 | 6500 | Optional |

| 8t/h | 8.9 | 997 | 6500 | Optional |

| 10t/h | 10.5 | 1197 | 7500 | Optional |

| 15t/h | 14.6 | 997 | 7000 | Optional |

| 20t/h | 20.7 | 997 | 7500 | Optional |

| 25t/h | 24.6 | 997 | 7500 | Optional |

| 30t/h | 28.6 | 997 | 8000 | Optional |

| 40t/h | 34.5 | 997 | 7900 | Optional |

| 60t/h | 48.7 | 997 | 6500 | Optional |

| 100t/h | 90.7 | 997 | 8500 | Optional |

Applications

Furnace coal fired chain grate stoker can be applied in chemical plant, university, food factory, beverage factory, cannery, textile mills, paper mill, sugar plant, central heating and other industries.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!